Description

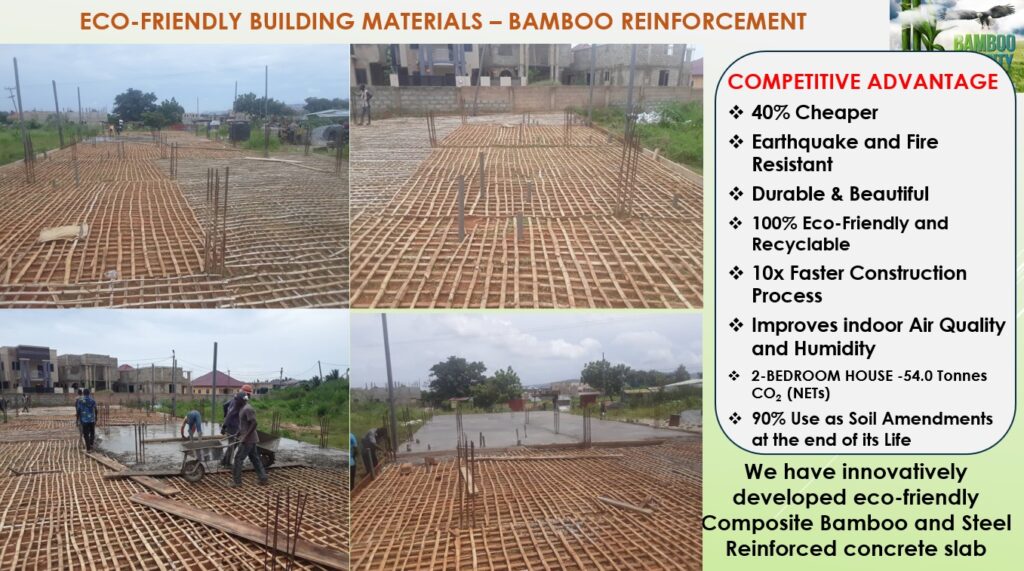

Our Bamboo Sticks/Slats/Splits are generally produced from whole culms for the construction reinforced concrete slabs, beams, column. After cutting the bamboo plant, it would be allowed to dry and seasoned for three to four weeks. Our Bamboo are allowed to dry for 30 days and split according to the suitable dimension. The bamboos culms are split or cut by using hand knife and machines equipment in the dimension of 10mm thick x 20mm wide x 6,000 mm long has been used for the preparation of the beam and slab reinforcement based on the Bamboo structural engineer’s design specifications/parameters. The thickness of the Bamboo Splits varies throughout its length since it is a natural material whose properties cannot be controlled strictly. Though steel has a tensile strength 2.5-3.0 times that of bamboo and a specific gravity 6-8 times that of bamboo, the tensile strength of bamboo is 3- 4 times that of steel when measured per unit weight (bamboo vs steel).

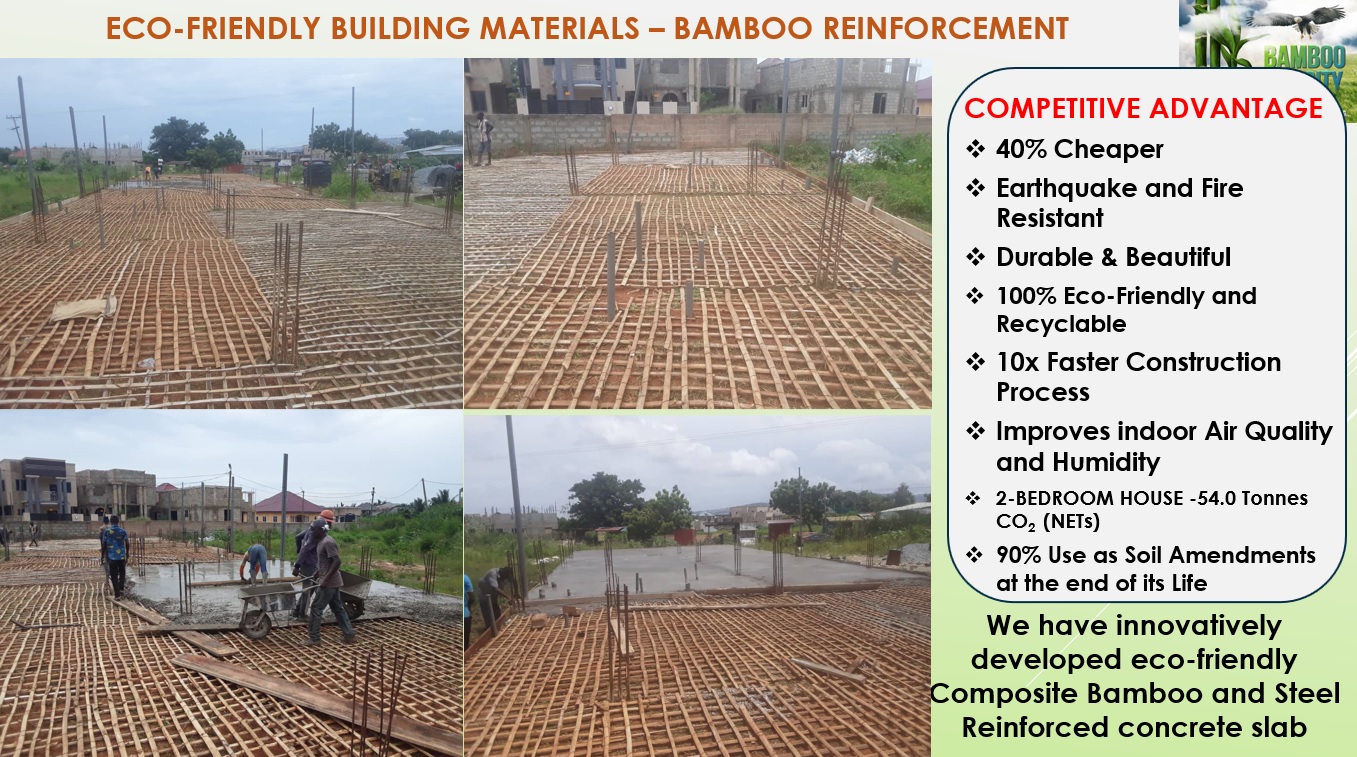

Concrete is the most consumed material, with three tonnes per year used for every person in the world. Twice as much concrete is used in construction as all other building materials combined. Concrete has excellent characteristic in compressive strength, but low in tensile strength. Steel commonly used in reinforcing material because of high tensile strength. The usage of steel as reinforcing material is limited because it is costly and also has an effect on air pollution during its manufacturing process. As an alternative to overcome this problem, Bamboo material has been used as a replacement of reinforcement in concrete. Bamboo is a suitable material because it is a natural material, cheap and also available material. Tensile strength test of bamboos has been performed to identify the yields stress of bamboos. From the test, result has shown that bamboo has a similar characteristic with steel and bamboo can be used as an alternative material for reinforcing concrete. However, the characteristic of bamboos showed high water absorption and low bonding strength between bamboo’s surface and concrete. At Bamboo Eco-City, we apply waterproofing agent to minimize water absorption and increase the bonding strength. From various tests conducted, it has resulted that bamboo give good potential as an alternative material in concrete reinforcement for cost-effective and efficient building and construction industry.

Process of getting the product.

BAMBOO RAW MATERIAL FOR CONSTRUCTION ANALYSIS

Currently, out of the approximately 400,000 hectares of Bamboo reserves in Ghana, about 85% is made up of Bambusa Vulgaris and Bambusa vulgaris var vitata (12 – 14m height and girth of 5 – 10cm at maturity); Oxytenanthera abyssinica (8 – 12m height and girth of 0.9 – 2.6cm at maturity) is about 10% and the rest 5% will account for the other species.

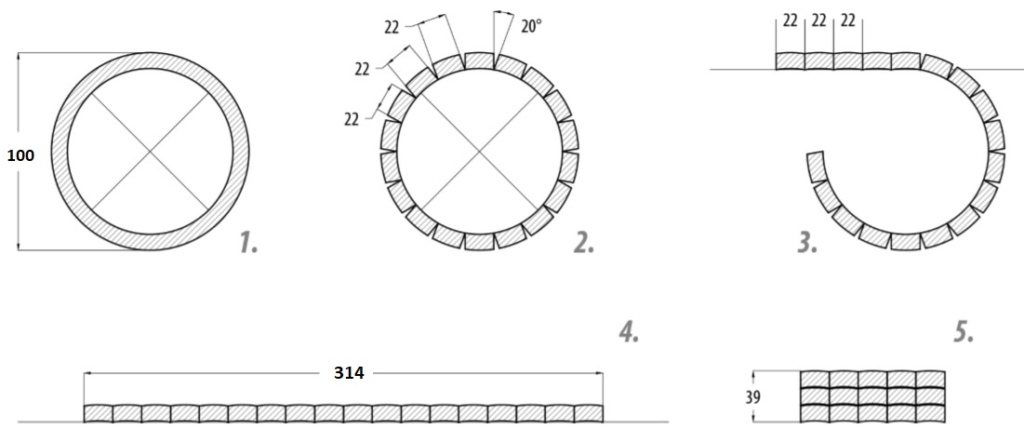

DETAILS OF BAMBOO POLE – BAMBUSA VULGARIS (8M HEIGHT AND GIRTH OF 100MM) CURRENTLY AVAILABLE FOR THE PROJECT

| The total area per split Bamboo is ~0.3m x 6.0m = 1.80m2

The total wall area of the 3-Bedroom affordable design = 220m2 The total Bamboo poles to be split to cover both sides of the wall (440/1.8) = 245no. Total no. of Bamboo poles for roof truss construction (7 poles per truss X 14) = 98no. Total no. of Bamboo poles for roof purlins (13×5) = 65no. |

Total no of Bamboo post (86.5/1.2m) = 72no.

Total no. of horizontal Bamboo bracing members between the posts (86.5/8m) = ~23×5 = 115n.

Grand Total no. of Bamboo pole for the construction of the 3-Bedroom affordable building (245+72+115+98+65) = 595no. Grand Total = ~600 – 1,200 Culms/Poles |

Key things that this product can be used for

PHYSICAL CONSTRUCTION PROCESS OF BAMBOO REINFORCED EARTH WALL IN NEPAL, ASIA

- BASIC FOUNDATION OF THE BAMBOO COMPOSITE HOUSING

15 DAYS FOR THE PLINTH TO BE READY FOR OTHER CONSTRUCTION

BAMBOO COMPOSITE WALLS BEING ERECTED AND SUPPORTED

BAMBOO COMPOSITE HOUSE READY TO RECEIVE ROOFING

ROOFING OF BAMBOO COMPOSITE HOUSE COMPLETED

BAMBOO COMPOSITE HOUSE RECEIVING LIME PLASTER

PLASTERING OF BAMBOO COMPOSITE HOUSE COMPLETED

PAINTING OF BAMBOO COMPOSITE HOUSE COMPLETED

COMPONENTS OF BAMBOO COMPOSITE WALL

LARGE BAMBOO COMPOSITE HOUSE READY TO BE PLASTERED

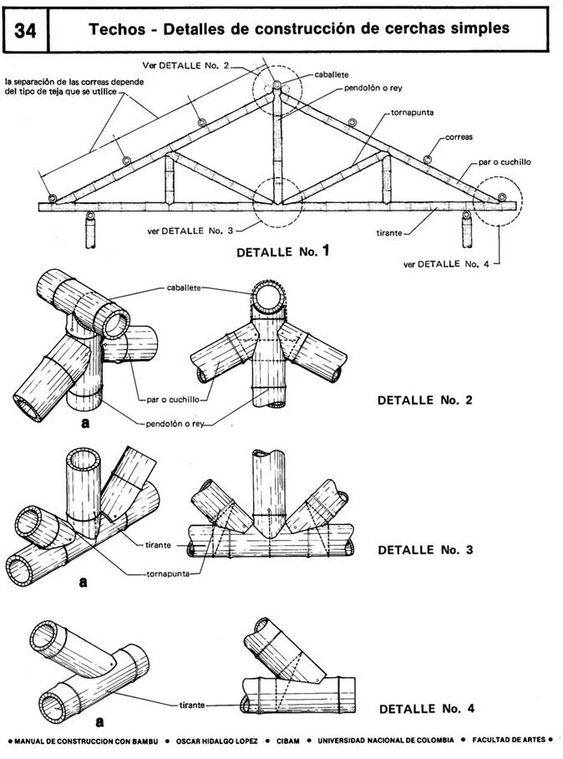

ROOF FRAMING DETAILS 1

Reviews

There are no reviews yet.